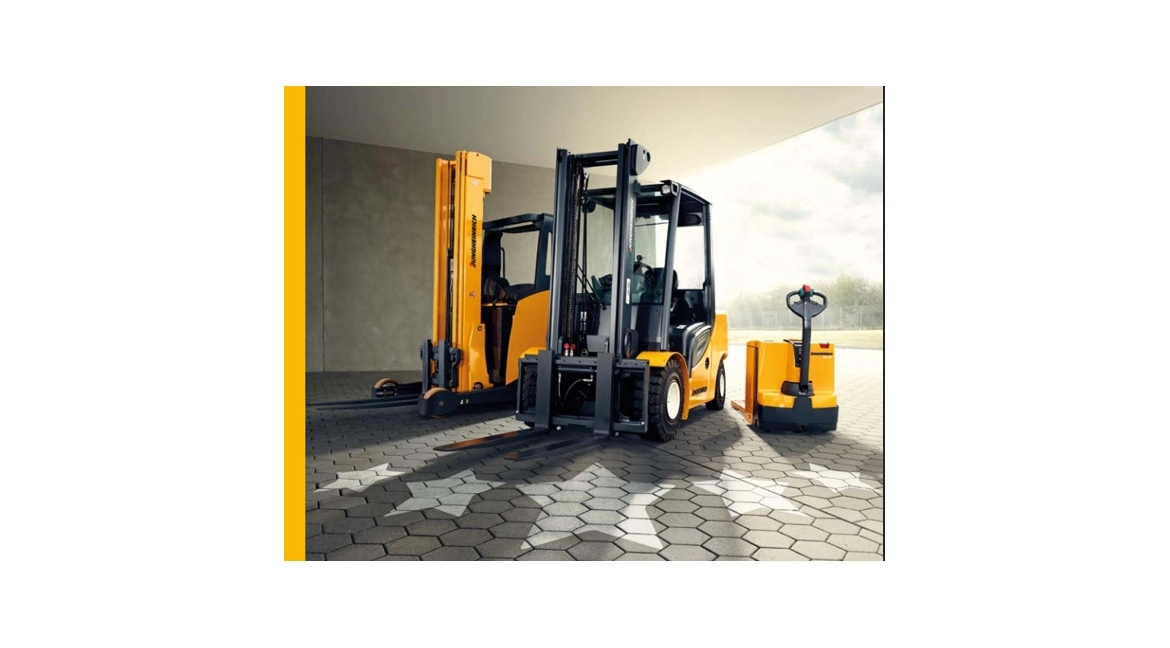

Jungheinrich full refurbished forklifts - From Used to NEw

Full refurbishments

Jungheinrich's forklifts are dismantled, inspected. Damaged components are replaced with original Jungheinrich spare parts. After repairs, the forklifts will be re-painted and then assembled with precision according to German quality and safety standards. Let's follow the step by step processes of our refurbished trucks.

Click here for available Used Equipment on our Shop>>

Step 1: Inspection of the forklifts

Thorough inspection according to strict Jungheinrich standards of quality is done to determine the condition. Essential safety components are replaced.

Step 2: Disassembly

Here all forklift components are being dis-assembled and cleaned, all operating fluids get discarded in an eco-friendly manner.

Step 3: Re-conditioning of the components

Depending on the forklift's condition, certain parts are replaced. Draw-bars and axles are re-conditioned. New bearings and bolts are mounted. The battery is either re-conditioned or replaced. Masts are dis-mantled, while hoses and chains are replaced as well.

Step 4: Surface Processing

The frame of the machine and the mast get cleaned, sanded, and repainted. The operator's overhead guard, steering system, side pushers, tilt cylinders and battery are all cleaned and repainted.

Step 5: Assembly

All the forklift components are re-assembled to restore the forklift back to its original state.

Step 6: Safety

Finally, the load test and pre-delivery inspection takes place. Each Jungheinrich machine comes out of this refurbishment process in premium German quality. Each with a safety certificate and our technicians' promise of quality, ready to go to its new home.

Jungheinrich South Africa offers attractive and flexible options to suite your warehouseing needs from used equipment, short term- and long term rental as well as outright purchases. Our attractive service options are available upon request.

Visit our main website for more product options available: www.jungheinrich.co.za